Microcement vs. Epoxy: What’s the Difference and Which Is Right for Your Floors?

When it comes to seamless floor finishes, two popular options are microcement and epoxy resin. Both offer sleek, durable finishes — but they’re quite different in terms of composition, application, aesthetic, and performance.

Whether you’re designing a high-end residential space, a commercial venue, or an industrial one, choosing the right material can impact the longevity, functionality, and feel of your space. Let’s break down the key differences between microcement and epoxy to help you decide which is the better fit for your flooring installation.

What Is Microcement?

Microcement is a cementitious coating applied by hand in thin layers over a wide variety of surfaces —floors, walls, ceilings, showers, joinery and furniture. It’s composed of cement or stone, water-based resins, additives, and mineral pigments. Thanks to its strong adhesion, microcement can be applied over existing tiles, concrete, plasterboard, or even wood.

Features:

Seamless application in tactile matte or smooth satin finishes

Natural, textured aesthetic

Extremely thin (2–3mm) with no need for demolition

Customisable colours and textures

Slip-resistant options available

Sealed for resistance to impact, stains and wear & tear

UV stable (won’t yellow over time)

What Is Epoxy?

Epoxy flooring is a resin-based system made from epoxy resins and hardeners, which chemically react to form a hard, plastic-like surface. It’s often poured over concrete to create a glossy, high-performance finish that’s ideal for heavy-duty use.

Features:

Durable and highly resistant to chemicals, oils, and abrasions

Glossy, polished look

Thicker application (up to 5mm or more)

Popular in garages, warehouses, and healthcare environments

Non-porous, naturally waterproof and hygienic

Requires a well-prepared substrate (usually concrete)

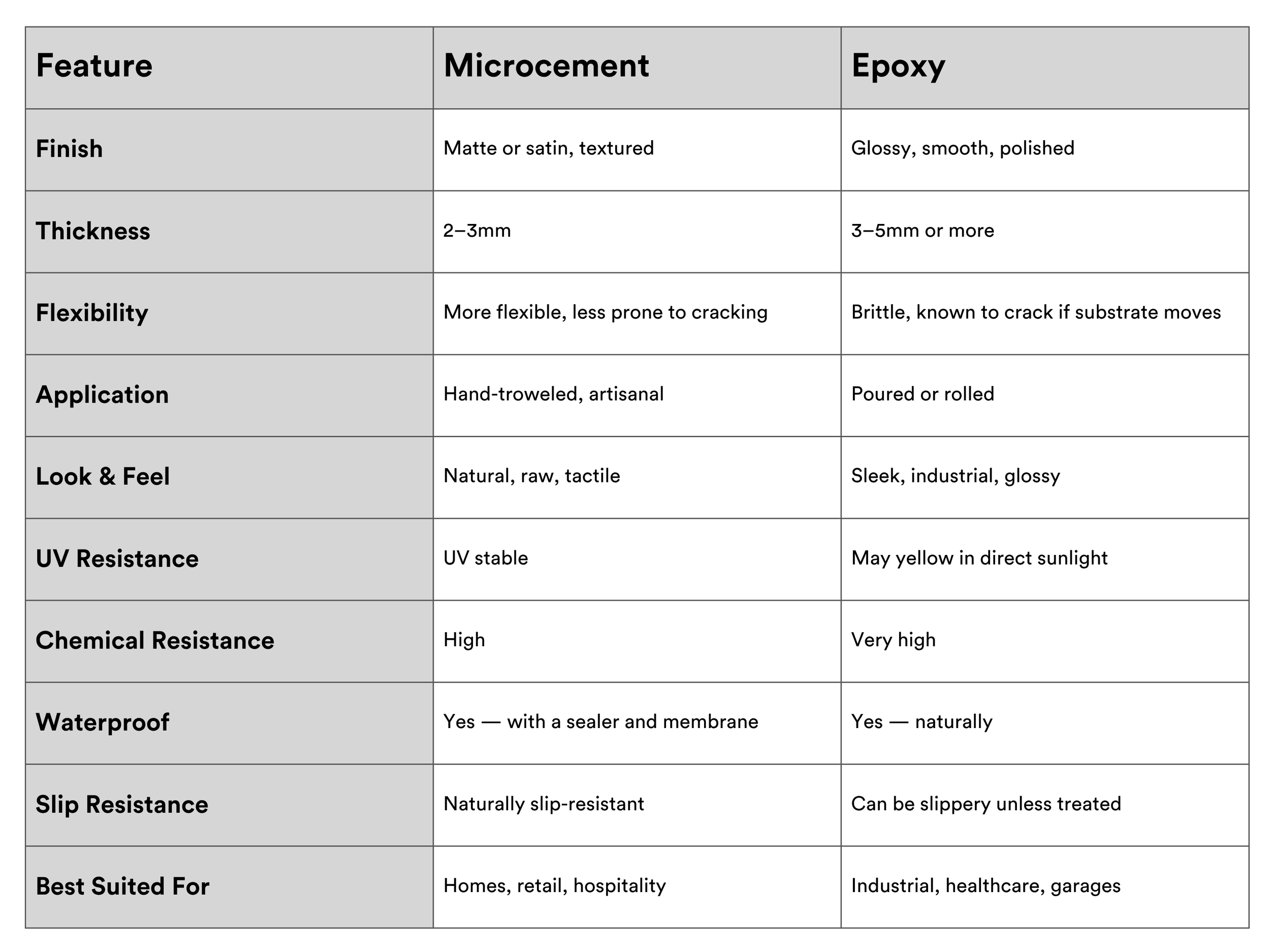

Side-by-Side Comparison

Microcement: Better For Design-Driven Spaces

If your priority is aesthetics and customisation with versatile usage, microcement shines. It’s favoured by architects and designers for its ability to create a seamless, continuous surface that blends into modern, minimalist design schemes. You can achieve everything from a smooth concrete look to a textured, plaster-like finish with soft transitions and natural movement.

Microcement is particularly well-suited to:

Bathrooms and wet areas (including over tiles)

Feature walls and ceilings

Curved surfaces

Benchtops and splashbacks

Hospitality and retail environments

Epoxy: A Heavy-Duty Workhorse

Epoxy is built for performance. With its high chemical and impact resistance, it’s commonly used in settings where durability and hygiene are non-negotiable. It’s also ideal for large-scale applications where ease of cleaning and a high-gloss finish are desired.

Epoxy flooring is commonly used for:

Garages and workshops

Commercial kitchens and medical facilities

Warehouses and industrial plants

Areas requiring high resistance to spills or traffic

Which One Should You Choose?

Choosing between microcement and epoxy depends on your project needs. For a refined, design-focused finish with natural character and versatile application across floors, walls, and joinery — microcement is the clear winner. For a tough, chemical-resistant surface in high-traffic or industrial environments — epoxy will give you the durability you need.

Need advice on your project? We’re experts in microcement application. If you’re unsure whether X-Bond will suit your project, just ask us! We’re happy to talk through your job.